Mission

The SEAO Sustainable Design Committee (SDC) promotes sustainable design practices for structural engineers in Oregon through leadership, advocacy, outreach, and education. The SDC’s primary focus is on the measurement and reduction of greenhouse gas (GHG) emissions associated with structural materials (i.e., structural embodied carbon).

Structural Engineering and Climate Change

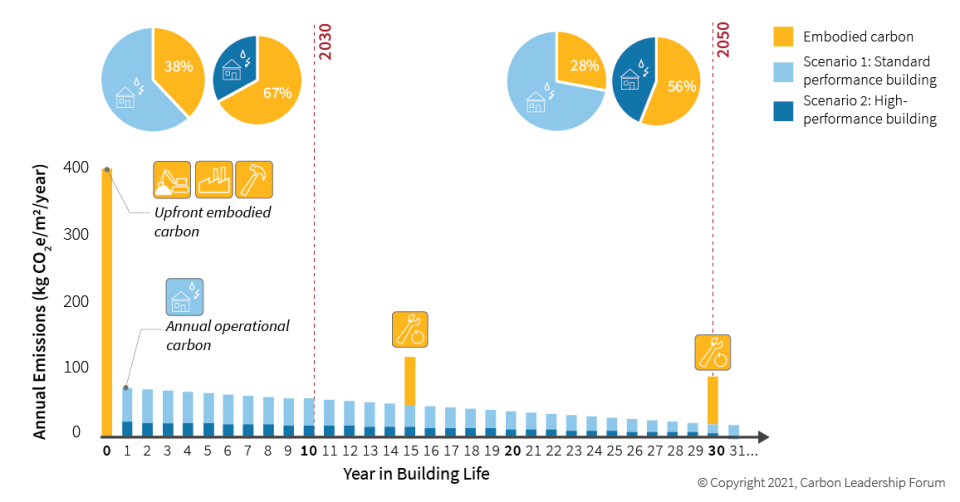

The structural engineering community is facing a watershed moment. Never has there been such an opportunity for structural engineers to be part of the solution in reducing humankind’s impact on the environment. For years, the green building focus has been on operational emissions, but more recently the focus has shifted to embodied emissions. Scientists believe that the time between 2020 and 2050 is a critical period in which global emissions must peak and then go to zero. We now know that the materials structural engineers specify represent a significant source of embodied emissions, and our community will be key to developing pathways to significantly reduce the industry's carbon footprint.

Furthermore, with continued reductions in carbon emissions associated with building operations (due to better energy performance and greening of the electrical grid), the impact of embodied carbon is becoming a larger “piece of the pie” of total carbon emissions associated with buildings.

Embodied Carbon of Structural Materials

Emissions associated with the material production, construction and demolition of buildings is currently responsible for approximately 7% of all global warming emissions. Many of these emissions are related to cements and metals, but all structural materials have associated emissions. Although 7% may seem small, due to the scale of materials that we design and specify, structural engineers can have a large impact on reducing carbon emissions. See table below for structural material quantities approximately equal to an average American's annual emissions.

- United States per Capita Annual Global Warming Emissions: 19,000 kg CO2eq

- Is approximately equal to:

- 70 cubic yards of reinforced concrete

- or

- 16 tons of structural steel

- or

- 180 tons of wood framing

Structural Embodied Carbon Resources

While many structural engineering organizations in Oregon are already measuring and reducing the carbon footprint of their projects, the following resources are excellent starting points to start and develop this process:

General Resources

SE2050 – Structural Engineering’s commitment program with a goal of zero net carbon structures by 2050. More than 100 structural engineering firms have joined the Program since 2019 and pledged to eliminate embodied carbon in their structures by 2050. For listing of current committed firms and helpful embodied carbon resources, please visit se2050.org.

The following are recommended resources from the SE 2050 website:

- What is Embodied Carbon?

- Embodied Carbon Estimator (ECOM Tool)

- Material Specification Guidance

- STRUCTURE Magazine Article featuring SE 2050 Data Collection: Data Insights From Over 500 Building Projects for Low-Carbon Structures

Carbon Leadership Forum (CLF) is a nonprofit organization at the University of Washington and is at the forefront of embodied carbon research and policy development. The following are recommended resources from CLF:

- Embodied Carbon Policy Toolkit, including “Embodied Carbon 101” (Written for policy makers, but still helpful distillation for engineers)

- Video Modules of Embodied Carbon 101, etc.

- Model Embodied Carbon Specifications

- Case Studies, including Holgate Library in Portland

- The Embodied Carbon Benchmark Report - Carbon Leadership Forum

- The California Carbon Report - Carbon Leadership Forum

Institution of Structural Engineers – UK-based engineering organization with well-developed embodied carbon processes.

Concrete

Concrete can be a significant contributor to a building’s embodied carbon largely due to cement content, production of which is estimated to be responsible for 8% of annual global emissions. The best way structural engineers can reduce the carbon impact of concrete is by specifying concrete with a reduced cement content. Common methods for reducing cement content include replacement of Portland cement with limestone (Type 1L) or supplementary cementitious materials (SCMs), such as fly ash or slag. Performance-based concrete specifications can also be effective, particularly for low-strength concrete mixes.

The following list includes recommended resources for low-carbon concrete.

- ACI 323 Low-Carbon Concrete Code

- Lower-Carbon Concrete Task Force

NRMCA regional benchmarks, Pacific Northwest (from 2023 CLF Baselines):

Specified Strength GWP in kg CO2e/m3 2500 psi 235.46 3000 psi 261.38 4000 psi 316.46 5000 psi 386.11 6000 psi 408.01 8000 psi 487.41 - Online Learning | NRMCA Webinars

- NCSEA Performance-Based Concrete Specification Guidance: Concrete Class Table

- City of Portland approved concrete mix designs with GWP values

News and Updates

The State of Oregon has completed a study exploring options for reducing greenhouse gas emissions that result from materials used in building construction with a final report published by the Building Codes Division in December 2024. It is possible that the next OSSC code adoption process (OSSC 2028) will include some language on structural embodied carbon. The SDC is actively monitoring these developments.

Join the SDC!

The committee is currently looking for more members! Join the committee and help work towards our mission of promoting sustainable design in structural engineering. We welcome all levels of experience.

ChairJo Ann OffillMackenzie

ChairJo Ann OffillMackenzie MemberDavid MarksKPFF Consulting Engineers

MemberDavid MarksKPFF Consulting Engineers MemberBrian DeMezaSimpson Strong-Tie

MemberBrian DeMezaSimpson Strong-Tie